Introducing 3D Printing Technology to Make Signs

Advertising signs is a must when you want to brand your business. Traditionally, making signs, signage, channel letters is a complicated and needs well-trained staffs to finish depending on the materials and style you need.

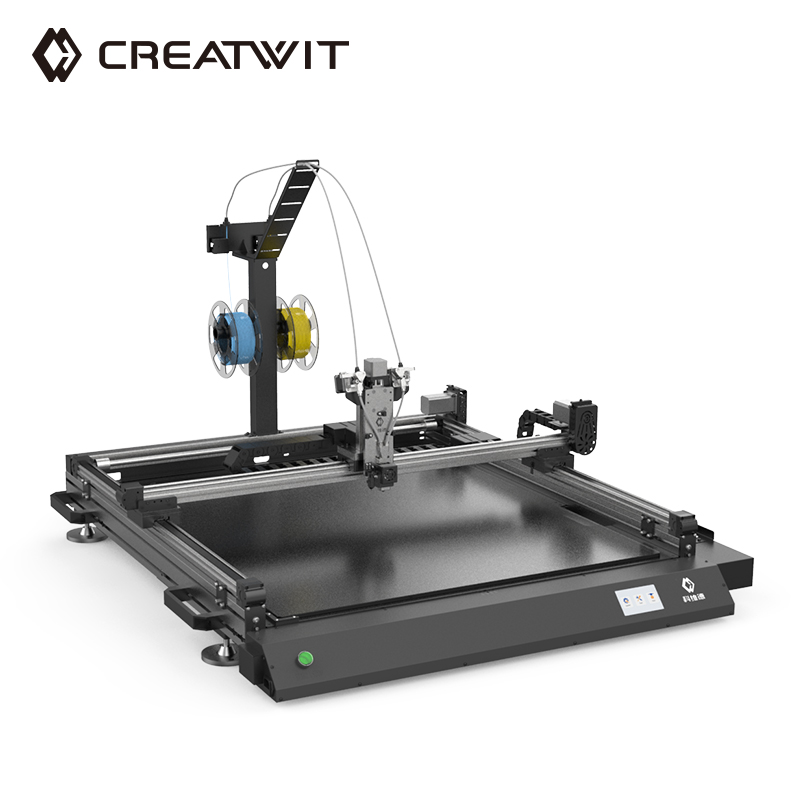

Introducing 3D printing technology to making signs is a bold trial. After a few years R&D, we released industrial-grade channel letter 3D printer -- K8, aiming to bring advanced 3D printing tech to signs manufacturing.

Average 9 steps VS 6 steps

Usually, it requires nine steps to finish a business signs : Signs digital model building -- Panel cutting-- Signs shape making -- Sign surface polishing--signs welding--circling the signs --Signs painting --Pasting acrylic plate -- LED light installation

Only six steps with 3D printer: Signs digital model building--Printing signs shell--Plate cutting and pasting--Light installation--Gluing

Capable of printing complicated styles

K8, built-in multiple printing styles, capable of printing complicated and beautiful graphics signs for you.

Cost-effective

3D printer uses environmental-friendly materials such as PETG or PDS to printer signs, which create no waste during the printing process.

Labor efficient

With 3D printing technology, signs manufacturing becomes almost less labor costly. In other words, it is more labor efficient. Moreover, an employee can handle 20 units of 3D printer since it is easy to operate

Other features of K8

Channel letter printing process automatic

Auto-color switching

Filament breaking-off detection

Auto-leveling