Why does 3D printing technology bring changes to advertising signs?

For enterprises that traditionally make advertising signs, before the introduction of 3D printer technology, the production of traditional advertising sign shell generally needs to go through multiple processes such as cutting, bending, slotting, welding and grinding, and the production process is very complex. Moreover, there are many defects in each traditional production process, the most important of which is to appear on people. Once there is a problem in each process, it may directly affect all subsequent processes. This is the short board of flow production. Therefore, many traditional advertising sign production enterprises urgently need to get a more convenient and fast production mode.

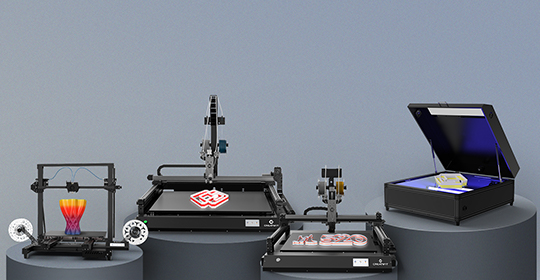

In recent years, 3D printer technology has become more and more mature and has been applied to all walks of life. For advertising word production, today's 3D printer technology can not only effectively improve the possible problems of advertising sign production line, but also greatly improve the production efficiency and reduce the labor cost. So why does 3D printing technology bring such changes to the traditional advertising word manufacturing? Kovid believes that there are three points:

First: manufacturers are no longer limited by the traditional complex technology, and everyone can make advertising words.

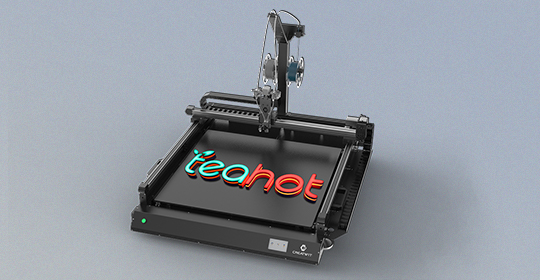

Compared with the previous advertising word production process: design, cutting, bending, slotting, welding, grinding, painting and a series of processes. Automatic production can be completed by using ad sign 3D printer. For example, kvid K6 advertising word 3D printer does not need 3D modeling. It only needs to import professional software to generate 3D files, which can be directly converted from 2D to 3D, and the slicing is simple and fast. Intelligent operation can be easily started without professional training. Compared with the traditional production process, the use of advertising word 3D printer can not only greatly improve the production efficiency, but also reduce the output of labor cost.

Second: the consumables used are not only cheap, but also environmentally friendly.

At present, the material price of 3D printing advertising words on the market is about 100 to 120 per kilogram, and most of the consumables used are biodegradable and repeatable materials, which have no pungent smell and do not need painting. They are recognized as environmental protection materials in the industry. Moreover, with the maturity of 3D printing technology, there is no waste in the printing process, and the actual cost is very low.

Third: transformation and upgrading of intelligent chemical plants.

With the popularity of mobile Internet and 5g technology, various industries are gradually transforming to intelligent chemical plants. As a traditional advertising word production factory, it needs complete equipment and sufficient space to produce advertising words. Equipment cost, material cost, factory site cost, store site cost, design cost, labor cost, etc. in this link, hundreds of thousands of people can have a complete process of making luminous words. With the ad word 3D printer, only one device is needed to realize the whole process of ad word production.

Moreover, the existing 3D printing technology also brings great convenience to manufacturers. For example, 3D advertising word modeling free software can automatically generate printing files by inputting the required text and selecting the font, or import the vector map into the software. The subsequent software development will be more intelligent, and the interaction between software and equipment will be realized in combination with Internet of things technology. Automatic modeling and cloud sharing can be realized on the mobile phone. Luminous word 3D printer can realize mass production of 3D luminous words, which is produced by intelligent chemical plant. One person can operate ten equipment at the same time, which greatly reduces the labor cost.

At any time, any industry should move forward with the changes of the times. For the advertising logo industry, there are corresponding changes in each era from the spray painting signboard, to acrylic composite process, and then to 3D printing technology. Only enterprises that closely follow the trend of the times and make corresponding changes can survive in the increasingly competitive market environment.